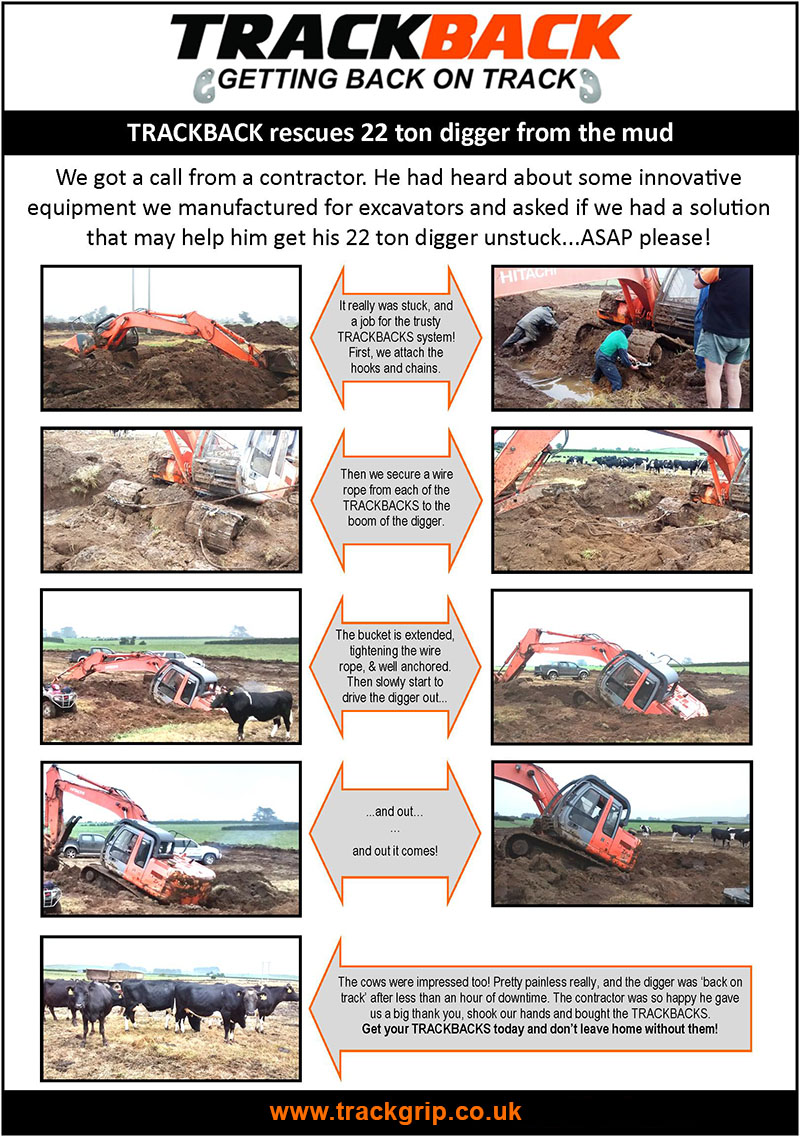

Trackback Rescues 22ton Excavator!

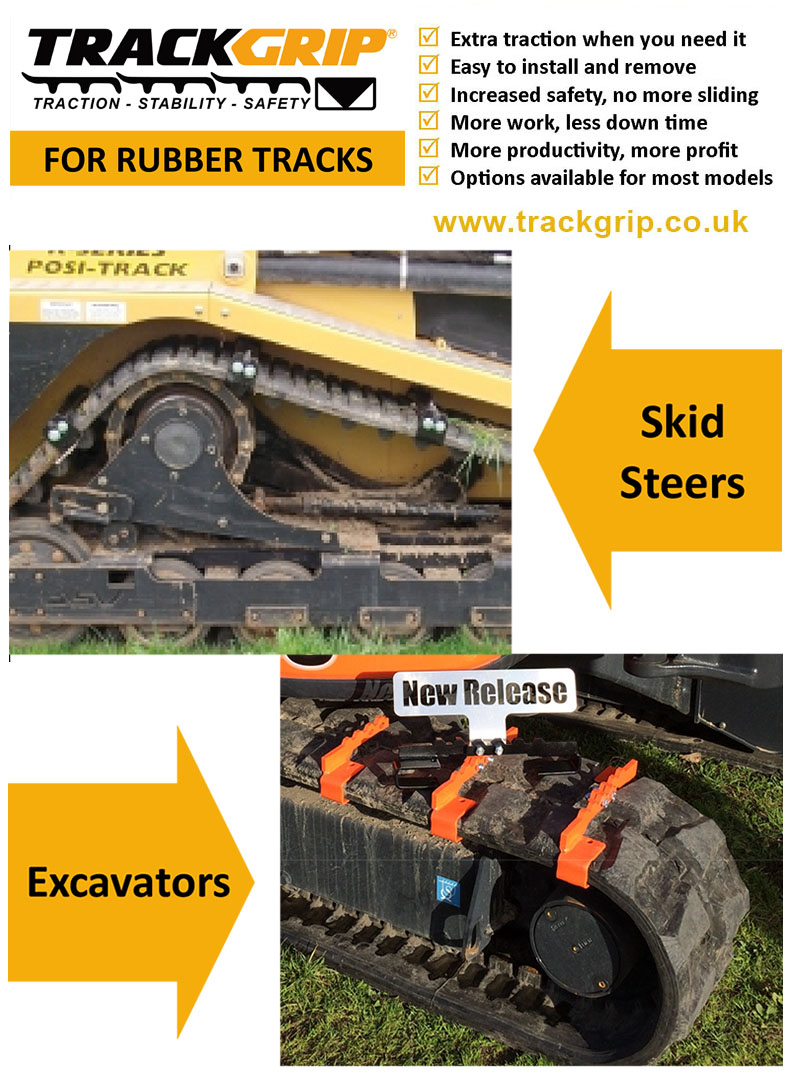

New Release: Extra Traction For Rubber Grips

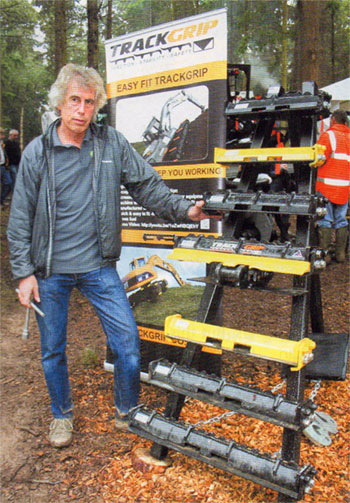

APF 2014 – Article

A major problem with excavator mounted attachments is the stability and safety of the base when operating on Slopes. NY Forestry spent time researching solutions to overcome this problem, including crudely mounted sections of angle iron attached to the tracks.

A major problem with excavator mounted attachments is the stability and safety of the base when operating on Slopes. NY Forestry spent time researching solutions to overcome this problem, including crudely mounted sections of angle iron attached to the tracks.

Then, coincidently, they came across a product designed and developed in New Zealand called TrackGrip which was purpose built for steel and rubber (all patterns) tracks and had an exceptional proven ‘track’ record.

The owner of the company explained that he had spent many years in R&D and made countless prototypes developing the TrackGrip, with particular attention focusing on fabrication and the grade of steel, which is Bisplate 400.

Not only do TrackGrip New Zealand claim to have the fastest laser cutter in the world, they can manufacture a TrackGrip to suit any individual’s design and requirements.

Stability on slopes is vastly improved, allowing operations to proceed in previously unworkable weather conditions and in otherwise inaccessible locations. The ease with which the TrackGrips can be fitted means no mechanic or welder is needed, nor is it necessary to transfer operations onto another machine.

Compared to fixed, aggressive grousers, the TrackGrip is far kinder to low loaders, roads, sensitive forestry areas, etc. They also increase fuel efficiency as the tracks are continually working and not skidding, sliding or struggling to power the machine in inhospitable conditions.

NY Forestry Ltd are the sole UK importer for TrackGrip products. If work is an uphill struggle or everything’s going downhill, it may be worth giving them a call!

- (Article featured in APF 2014 publication)